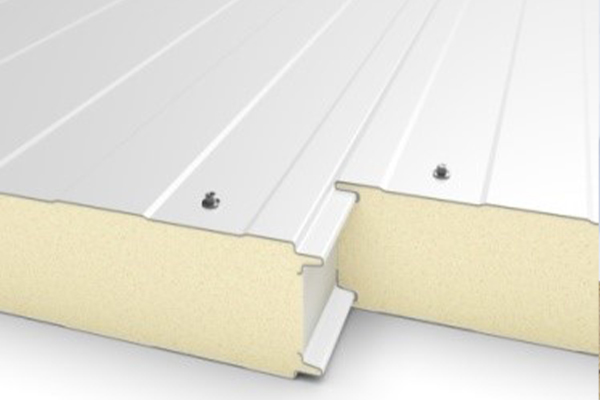

PU Sandwhich Panel

PPGI Sheet : Material Specification

- Sheet thickness 0.36 mm to 0.50 mm

- Color Off white or Any RAL

- Zinc coating AZ40-60 GSM

- Coating Mass: Top Coat 15~20 micron & back 7 micron

- Tensile strength 380-400 Mpa & Yield strength 368 MPa

PU Sandwich Panel: Specification /Technical Data

- Core Material: Polyurethane Foam

- Density 40-45(+/-2) kg/m3

- Available Size( Width): Roof Panel-820mm & Wall Panel 980/1180 mm

- Thickness : 40 mm, 50 mm, 75 mm, 100 mm & 150 mm

- Length: Max 26 feet or Customized

- Compressive strength 150-191 kPa.

- Thermal conductivity 0.018-0.024 W/m.k.

- Fire Resistance: PU Sandwich panel will stay intact to maintain its load-bearing capacity and integrity for 30 minutes.

- Fire retardant class B2 with metal sheet

Features:

- High quality Galvanized Steel outer shin hence very good life of more than 25 years

- EPS/PUF Insulation of high quality hence excellent thermal and acoustic installation

- Light weight and easy to install

- Bare minimum steel frame work hence very economical

- 100% leak Proof

- Available in customized lengths

- Energy saving

- Maintenance free

- Easy of dismantling and quick relocation

Applications/uses:

- All types Industrial shed / Poultry Control Shed

- Cold Storage/ Food Processing Factory

- Ware house

- Malls

- Commercial complex

- Prefabricated guest house

- Site office ,Labor colony

- Clean Room

- Pharmaceuticals

- Hospital OT Room

- IT Park Hostels

- Schools, Canteen,

- Rooftop Cottage

- Security posts

- Rest rooms

- Defense Post etc.

Cold storage facilities: PU panels are the prime choice for cold storage facilities due to their exceptional thermal insulation properties. They help maintain consistent low temperatures and reduce energy consumption for cooling.

Clean rooms: PU panels are well-suited for clean rooms because they offer good thermal insulation and can be produced with smooth surfaces that are easy to clean and maintain.

Building walls and roofs (wider range): PU panels can be used in a wider range of building applications compared to EPS due to their increased structural strength. This includes walls and roofs of industrial, commercial, and agricultural buildings, particularly those requiring good insulation and some load-bearing capacity.

Modular buildings: Similar to EPS, PU panels are also used in constructing modular buildings due to their fast assembly and good insulating properties.

Other considerations:

Fire resistance: PU panels can be formulated with fire-retardant additives to improve their fire resistance properties. This is crucial for buildings with stricter fire safety requirements.

Cost: PU panels are generally more expensive than EPS panels due to the higher cost of PU foam compared to EPS.

Moisture resistance: PU foam has good closed-cell structure that resists moisture penetration. However, for applications with very high humidity or direct water exposure, additional moisture barriers might be needed.

In conclusion, PU sandwich panels offer superior insulation, better structural strength, and wider application possibilities compared to EPS panels. However, they come at a higher cost. The best choice between EPS and PU panels depends on your specific needs, prioritizing cost-effectiveness and basic insulation (EPS) or superior insulation, structural strength, and fire resistance (PU).