Sandwich Panel

Sandwich panels are used in facades, partition walls and ceilings. The most typical applications include industrial, office and commercial buildings, sports halls, warehouses and power plants. The panels are also suitable for food industry construction and demanding clean room applications.

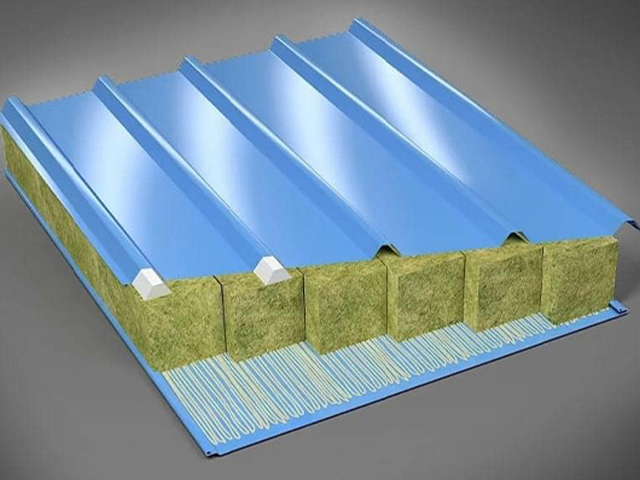

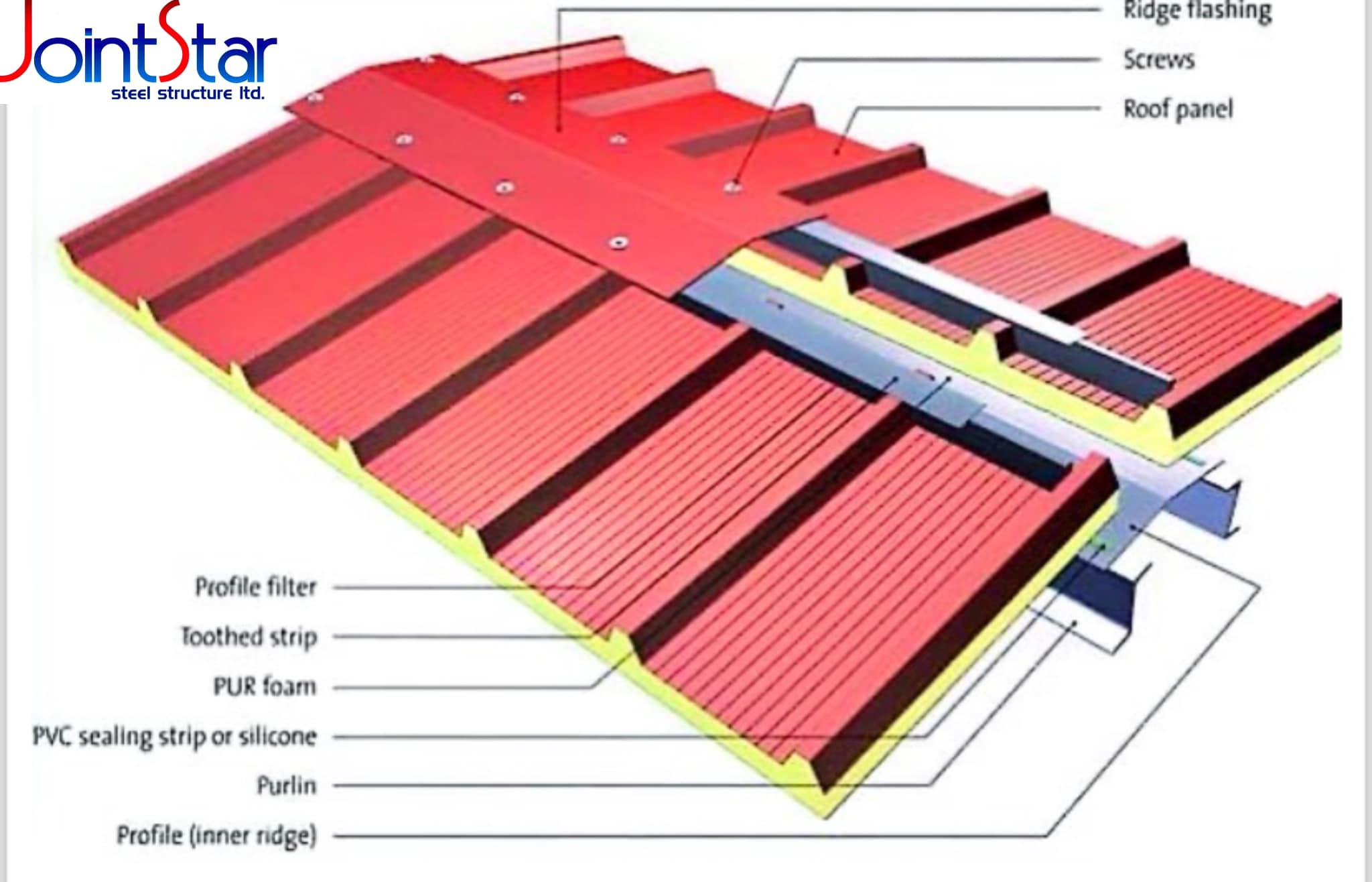

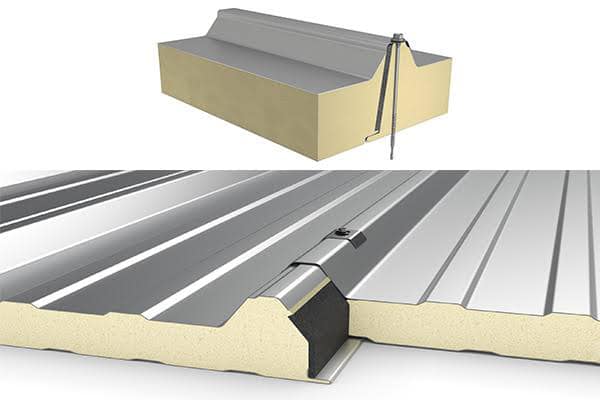

Sandwich panels are cost-efficient prefabricated elements that consists of an inner insulation core between two colour-coated steel sheet layers. The insulating core can be mineral wool, polyurethane or polystyrene. Sandwich panels have been applied successfully in many buildings and applications due to indisputable benefits resulting from this modern way of construction. More tradition-bound agriculture customers have also recognised the speed of construction, ease of maintenance and adaptation that a lightweight panel envelope contributes to a building.

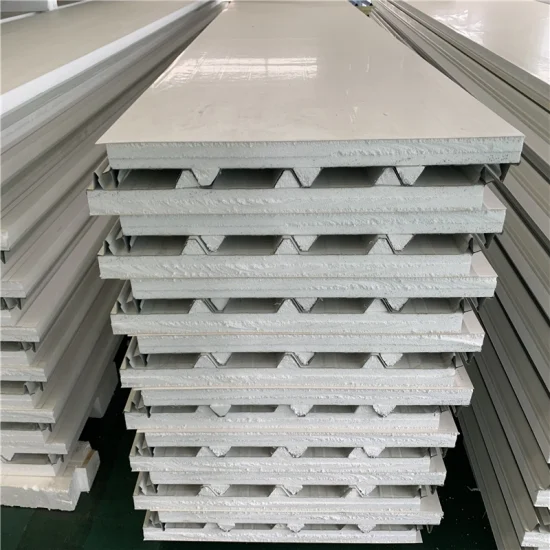

Our insulated cold storage panel system has very low U-values and a high degree of air tightness. Cold storage panel thicknesses from 120 mm to 200 mm and different coating options for higher level of hygiene make them suitable for different types of cold storages.

In addition to sandwich panels, ‘JSSSL’ offers a wide range of steel construction materials and tools needed for their installation. We also provide a comprehensive selection of professional services and full technical support.

Applications/Uses

Poultry Control Shed, Pharmaceuticals, Food Processing Factory, All types Industrial shed, Ware house,Malls, Commercial complex, Prefabricated guest

house, Site office,Labor colony, Shelters, Bunt z houses,IT Park Hostels, Schools, Security posts,Rest rooms, Defense Post etc.

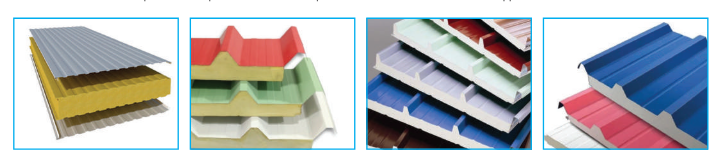

EPS Sandwich Panel

Owing to our rich industrial experience and knowledge, we are engaged in presenting high quality Eps Sandwich Panel. This EPS insulation is manufactured in compliance with international quality standards utilizing high grade raw material of standard quality and cutting-edge technology. Our renowned clients can avail this product in plethora of designs, patterns and prints. We offer this range in different specifications as per the needs of clients and available at market leading prices.

Features

- Excellent strength

- Splendid finish

- Optimum quality

PU Sandwich Panel

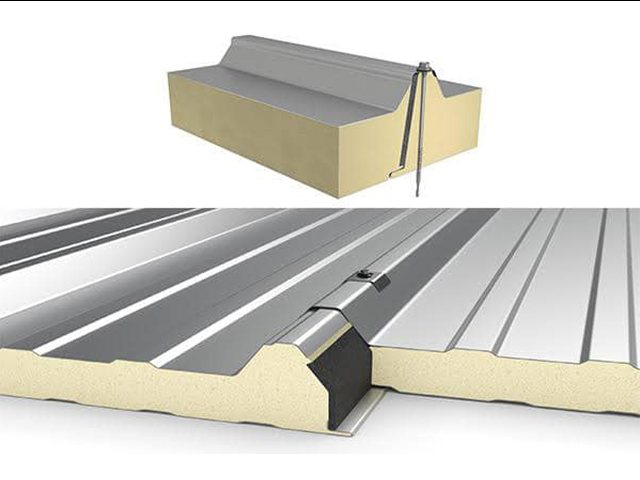

Polyurethane foam sandwich panel is fit for the projects which have serious require of keeping warm. Polyurethane core material is considered to the best material in keeping warm and thermal insulation. The Polyurethane block material become steady after it froth, then combining with metal plates. The characteristics of this technique are: the polyurethane froth, after this chemical reaction is stable, we cut the polyurethane into pieces which with different thickness. The polyurethane sheet material has stable physical performance, it can combine with pre-painted hot galvanized steel sheets or stainless steel sheet, the surface is smooth and the whole performance is excellent.

Features

- High quality Galvanized Steel outer shin hence very good life of more than 25 years

- EPS/PUF Insulation of high quality hence excellent thermal and acoustic installation

- Light weight and easy to install

Bare minimum steel frame work hence very economical

100% leak Proof - Available in customized lengths

- Energy saving

- Maintenance free

Ease of dismantling and quich relocation

Applications/Uses

Poultry Control Shed, Pharmaceuticals, Food Processing Factory, All types Industrial shed, Ware house,Malls, Commercial complex, Prefabricated guest

house, Site office,Labor colony, Shelters, Bunt z houses,IT Park Hostels, Schools, Security posts,Rest rooms, Defense Post etc.